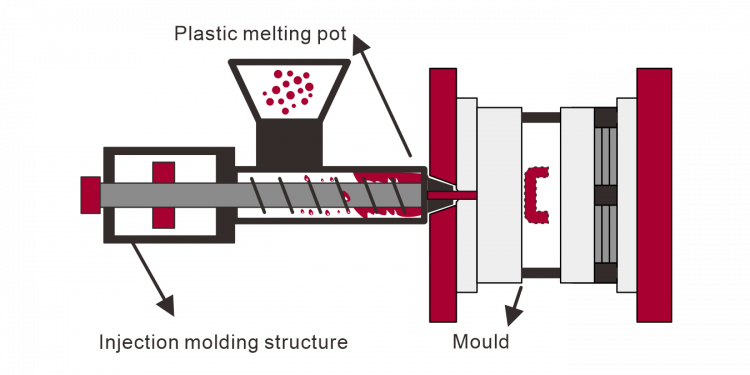

As you may be aware, injection molding supplier is a speedy yet efficient method of mass-producing plastic objects like kitchen utensils, furniture, store boxes for skincare products as well as toys. Any ordinary plastic thing you encounter is almost certainly a result of this production process. A molded object is made by pouring molten polymer into a metal mold at high temperature and pressure, then allowing it to rest and harden to adapt to the mold’s structure Injection molding online.

Know your needs

To begin or start, you must first determine your requirements. Confirm the needs with the China mold suppliers and double-check that everything is in order. Whenever you need a million rounds automatically fired from an injection mold, you should know what iron and mold base will be used, whether a hot tip will be incorporated, and also what kind and sort of plastic injection mold will be utilized.

When do you need a custom mold?

You’ll want an injection mold if you want to produce a custom item or create adjustments to an existing service design. Plastics, glasses, ceramics, alloy steels, and metals are among the materials utilized in injection molds. As a result, injection molds are used to create anything from phone casings to plastic knobs to pocket watches and jewelry components.

How do you choose a Chinese injection mold manufacturer?

When looking for plastic injection producers to outsource, do your homework. When choosing a Chinese injection mold provider, you should always keep the following list in mind:

- Obtain information from them and complete the assignment.

- Tool steel has a long history.

- Is it a mistake to engage in a workshop and hardware?

- everything is in order (established method) a project management plan that depicts every stage of the construction process and provides updates

- Quality Assurance Programs

- System of Verification

- Do they have any prior experience with your good or service?

- Can they perform everything in-house? How much capability do they have?

- Capability as well as what it is right now as you place your P.O.

- Is it possible for them to serve you globally?

How to Collaborate with a Plastic Molding Business & Manufacturer?

After you’ve completed the required stage, you’ll need to decide which one will work best for you to begin building a harmonious connection with a fresh plastic injection molding factory. The payment conditions are the first item to think about. Payment on time ensures that the firm runs smoothly and efficiently.

Agreement

An agreement should be in place that spells out the payment terms, as well as your or their duties. It’s almost as though you’re joining your vendors halfway. Keep in mind that the suppliers or vendors may have numerous clients to attend to, so some issues may not even be addressed immediately away.

Second, to ensure that the plastic mold production is on timetable, request that the plastic mold maker create a mold production time schedule and a mold trial cycle times, and also that they submit you a regular report with production pictures each week. It could be a safer method of keeping the timeline since you can keep a close eye on products each day because you are hundreds of kilometers away.

Pose inquiries.

Bring Question About Project Planning Method. A well-organized management process would be found in a developed China mold manufacturing. Even with the same mold-making power, an important part of project management may make a huge difference.

It’s critical to anticipate potential hazards and take measures before they occur; a skilled project leader can always steer the program in the proper direction. Do they present a manufacturing plan and acknowledge that they will adhere to it? When they supply specimens, do they include injection setting and measurement reports? Etc.

The argument over plastic and pollution

It’s hard to discuss plastics without mentioning their environmental impact. However, we are becoming more ecologically sensitive as a society, and the plastic injection molding sector is following suit. Here’s how to do it:

Plastic injection molding uses a lot of recycled plastic. While it may not function as well as fresh plastic, it’s a much more environmentally responsible option that can help reduce production expenses. Plastic injection molding machines require electricity to operate.

On the other hand, today’s electronics are claimed to use 20 percent to 50 percent less electricity than those from a decade ago, thanks to technical advancements. Furthermore, you should choose a piece of electric equipment over a hydraulic pump when given the option because it is more fuel-efficient.

What should be done with the mold?

Despite not being used, the injection mold and accompanying tools are usually retained in the company’s production plant. This can be dangerous because the supplier could utilize your mold to make items for themselves or other buyers without telling you. You can keep the injection mold at the facilities of a reputable 3rd person in China to limit the chances of this ever occurring. Send it to the provider before manufacturing begins, then pick it up after it is completed.

Customization

Customized plastic injection molding in China is particularly useful whenever plastics demand additional processing. Cleaning components, over-molding, painting, piercing holes, block-printing, silk screening, or incomplete sub-assemblies are all examples of secondary processes. They can take the opportunity of lowering labor expenses in China to cut prices for their clients significantly.

Whenever high-end second-op grinding and balancing equipment is required for plastic injection molding parts with tolerances that cannot be achieved during molding processes, they can use them.

Injections mold/molding solution has a number of advantages.

The personnel received extensive training in order to provide the highest level of service possible for the project.

- The injection molding tooling engineer, technical expert, shipping, and mold production process manager are all working together to ensure or confirm that clients are completely satisfied.

- Client demands are being met, such as optimizing molds and saving a lot of labor before mass production.

- For successful programs for clients, good management strategies are used.

- Mold problems are investigated and improved to match client standards and expectations, with a 100% guarantee.